Industrial Container Recycling Simplified By Belt Oil Skimmer

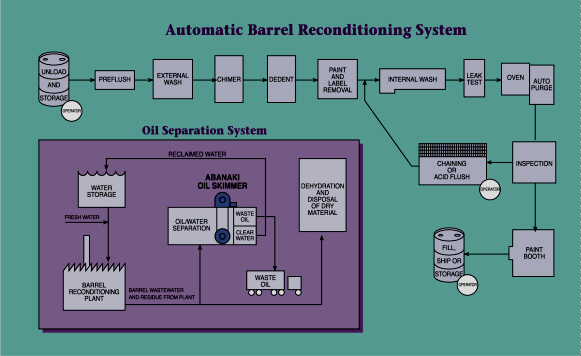

Barrel Reconditioning Industries (BRI) of Cottage Grove, MN builds recycling systems for both metal and plastic containers, including lubricating fluid drums and barrels.

A typical BRI system consists of several integrated machines or stations, including a solvent preflush and a high pressure water wash. The water wash presents two distinct problems. First, oil and grease contaminated wash water can plug spray heads and filters, reducing system effectiveness. Second, disposing of wastewater contaminated with oil, solvents and other hydrocarbons costs as much or more than disposing of a used barrel.

To reuse the barrel reconditioning water – oil, solvents and other hydrocarbons must be removed along with solid contaminations. Jay Ahern, BRI’s president uses an Oil Grabber® Model 4 made by Abanaki Corporation, Oil Skimmer Division of Chagrin Falls, OH. The belt oil skimmer specified by BRI is made of stainless steel for trouble-free operation under high temperatures and harsh chemicals.

The skimmer makes use of the differences in specific gravity and surface tension between oil and water. These physical characteristics allow a moving collector in the shape of a belt, operating on a motor and pulley system, to attract oil and other hydrocarbon liquids from the surface of the fluid. After traveling over the head pulley, the belt passes through tandem wiper blades where oil is scraped off both sides of the belt, and discharged. The tail pulley has flanges which allow it to roll freely on the inside of the belt without becoming dislodged. It requires no bearings and does not need to be fastened to the tank. If turbulent conditions exist, an optional tether and cage assembly prevents the tail pulley from being dislodged.

BRI makes a wide variety of equipment for different types of containers,so flexible design options are important. The Abanaki belt oil skimmers accommodate many different configurations with customized belt lengths, different mounting configurations and various motor options.

According to Ahern, “Over the years we’ve tried a lot of different types and manufacturers – coalescers, tube skimmers, disk types and others. But, we always come back to Abanaki belt oil skimmers. Even when we are using coalescers and filters, the Oil Grabber improves their efficiency by preventing an overload of too much oil.”

Edited for length: Published in Hazardous Materials Management.