What is an Oil Skimmer?

Oil skimmers are simple, dependable and effective machines for removing oil, grease and other hydrocarbons from water. The floating oil adheres to skimming media, such as a belt, tube, rope, mop, or disk. The media then travels back into the machine and is wiped clean. Weir style skimmers use a pump to collect floating oils.

Understanding the Basics

All oil skimmers rely on the fluid properties of specific gravity and surface tension. Most use a moving medium to remove floating oil from the fluid’s surface. Floating oil and grease cling to skimming media more readily than water. This allows media in the shape of a belt, disk, drum, etc. to pass through the fluid surface and pick up floating oil and grease while rejecting most of the water. The oily material is subsequently removed from the media with wiper blades or pinch rollers.

Watch Abanaki’s Oil Skimmers in Action

Applications for Oil Skimmers

When properly selected and applied, oil skimmers are highly economical solutions for separating oil from water to allow its reuse or safe disposal. However, there are certain applications that can expect optimal results. Typical applications best suited for oil skimmers encompass wastewater sumps, coolants and cutting fluids, heat treating operations, parts washers, food processing facilities, parking lots, garages, service facilities, outdoor ponds/lakes/basins, recovery/monitoring wells, remediation processes, and many more

Choosing the Right Type of Skimmer

There are several types of industrial oil skimmers. Choosing one best suited for your application will maximize oil removal while minimizing capital outlay and skimmer operating costs.

You may define the application in terms of the following characteristics:

- Operating conditions

- Hazardous materials

- Temperature/viscosity

- Skimmed water content

- Residual oil

- Portability

- Tank or sump characteristics

- Size, design, shape, and location installation

Determine the Right Design

For industrial oil skimming, there are six basic designs commonly used in moving media skimmers. (Suction skimmers are excluded, as they are generally unsuitable except for relatively thick (1/4 inch) layers of oil; otherwise they tend to ingest large amounts of water.) In more demanding situations, skimming is a cost-effective means of removing most of the oil before using more complicated and costly treatments, such as coalescers, membrane filters and chemical processes.

Consider All the Options

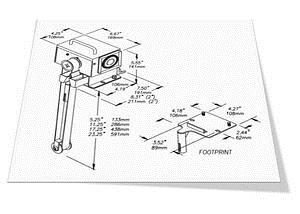

All moving media skimmers use motors to move the belt, tube, disk, etc. While many are designed with standard, industrially rated, continuous-duty motors and also may use fully enclosed speed reducing drives, some can be specified with a number of motor options. Consider also any optional equipment that may be available with the skimmer you are evaluating. Accessories allow customized systems that can ease installation and optimize performance. Some of the more common options include: special drive components, mounting stands and adapters, shelters/ enclosures, controls/accessories, concentrator, and heaters.