- Multiple site usage – easily moved from one place to another.

- 6 gph removal rate.

- Can be used in tanks as shallow as a few inches.

- Requires no tank modifications in most applications.

- Maintains skimming efficiency in fluctuating fluid levels.

- Prevents plugging of spray heads and filters.

- Conserves parts wash water and prevents recontamination of parts as they are removed from wash tank.

- Saves coolants by removing tramp oil.

Tote-It® Portable Belt Skimmer

$1,687.00 – $1,921.00

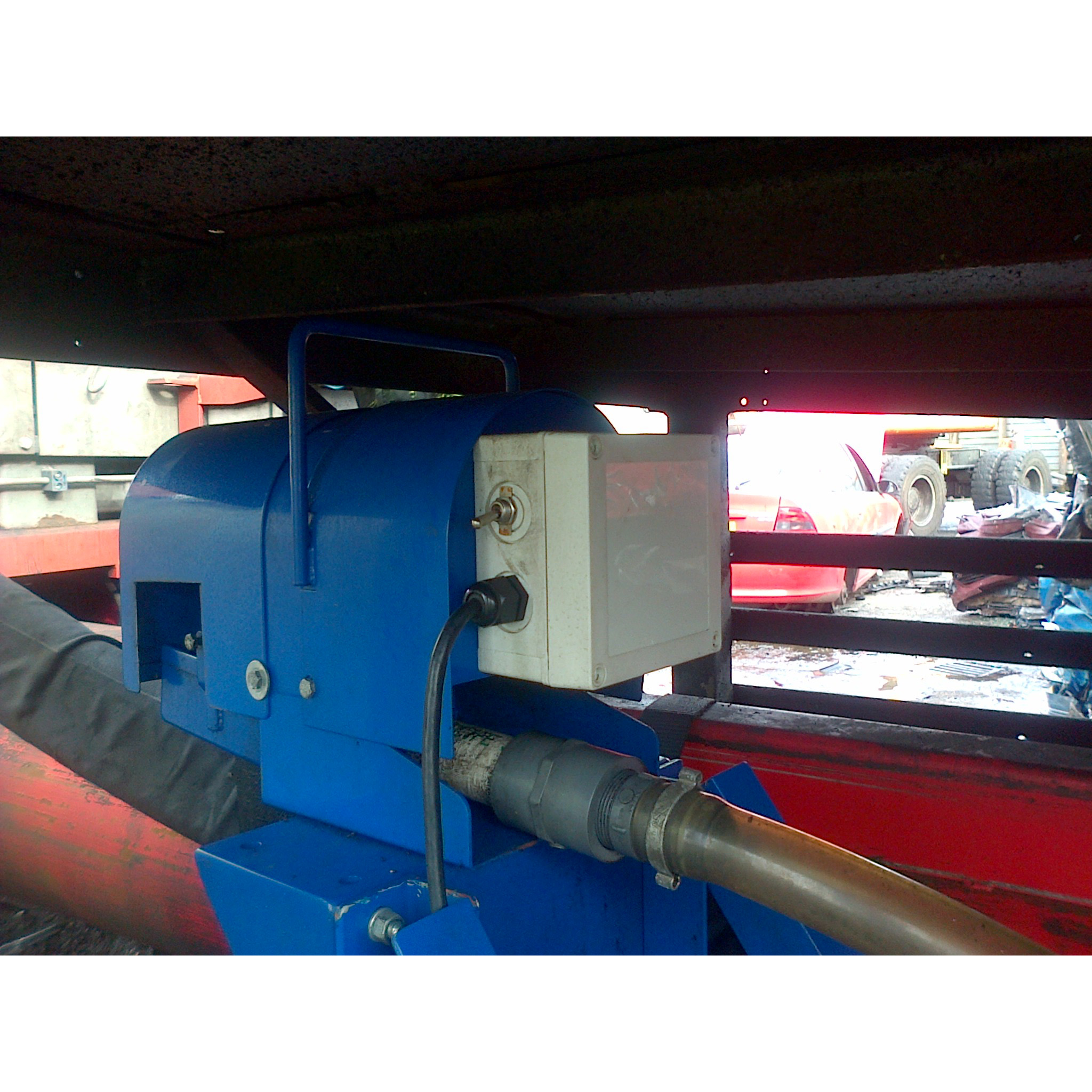

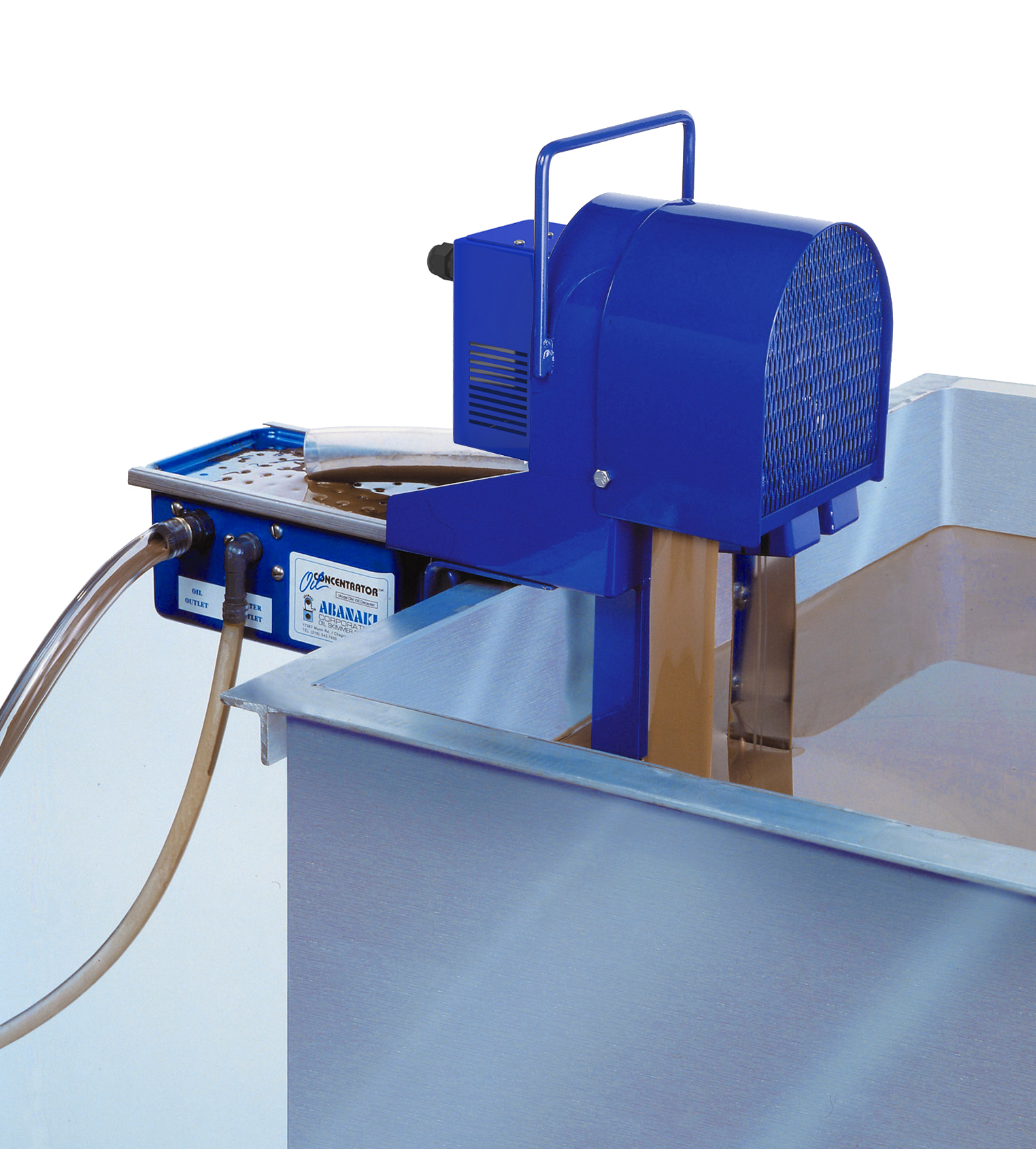

The Tote-It’s patented design is a dependable and effective means of removing free floating oil from water. The single assembly unit can be used in any application where 115 VAC, 60 or 220V, 50 Hz power is available. The Tote-It utilizes a continuous belt and wiper to remove up to 12 gallons of oil per hour from the fluid surface. The belt operates on a motor and pulley system attached to a stabilizer bar that is immersed in the contaminated liquid. After traveling over the head pulley, the belt passes through tandem wiper blades where oil is scraped off both sides of the belt, and discharged through a 1-1/4 in. ID hose. The tail pulley has flanges which allow it to roll freely on the inside of the belt without becoming dislodged. It does not need to be fastened to the tank. The Tote-It is especially well suited for parts washing and machining center applications. By removing surface oil from a wash tank, the parts will not be recontaminated as they are withdrawn. Removing tramp oil from a coolant tank prevents excessive smoke and fumes due to oil burning during cutting operations. It also reduces bacteria growth in the tank, along with the resulting odor.

| Oil Removal Rate: | 12gph (45.6 lph) with 4 in.( 10 cm) wide belt 6 gph (22.8 lph) with 2 in.( 5 cm) wide belt (Removal rate is based on 30 weight oil in water.) |

|---|---|

| Motor: | Fractional hp gear motor, 115VAC, 60 Hz |

| Belt Width: | Specify 4 in. (10 cm), or 2 in. (5 cm) |

| Belt Length: | Standard lengths from 18″ to 5′ center to center (maximum length 10′) |

| Belt Material: | Specifically selected for your application |

| Wiper: | Nitrile standard; CRV rubber, Ceramic/UHMW hybrid and Stainless steel optional. Specify wiper material based on temperature and fluid compatibility. |

| Mounting Method: | Flat base mount with oil discharge through a 1-1/4 in. I.D. hose. See installation drawing. |

| Mounting Area: | See installation drawing. |

| Weights: | Complete assembly with stabilizer bar, tail pulley, and steel belt: 2 in. : average 34 lbs. (15.4 kg) 4 in. : average 36 lbs. (16.3 kg) (Note: optional hose w/clamp and adapter weighs 2 lbs. (0.9 kg).) |

| Options (Specify): |

|

Wipers

| Temperature of Liquid | pH 3-5 (acidic) | pH 6-8 (neutral) | pH 9-13 (alkaline) |

|---|---|---|---|

| 33°F-180°(0.5°C – 82°C) | CRV | nitrile | CRV |

| 181°F-212°F(83°C-100°C) | CRV | CRV | CRV |

Belts

| Temperature of Liquid | pH 3-5 (acidic) | pH 6-8 (neutral) | pH 9-13 (alkaline) |

|---|---|---|---|

| 33°F-180°(0.5°C – 82°C) | CR steel, elastomer, polymer | CR steel, polymer, HT polymer | polymer, HT polymer |

| 181°F-212°F(83°C-100°C) | CR steel | CR steel | CR steel |

Standard Configuration: The standard Model 4 is supplied with a motor belt guard, spring-loaded adjustable wiper blade assembly, skimmer belt, tail pulley, and assembly instructions.

Specification Notes: The Model 4 is UPS shippable.Consult factory for recommendations covering operating conditions not listed here.

Related products

Abanaki Corporation Oil Skimming Division

17387 Munn Road

Chagrin Falls, OH 44023

Phone: (440) 543-7400

Email: skimmers@abanaki.com

Fax: (440) 543-7404

ISO 9001:2015 Certified Company